Takada Industries Czech Republic is a daughter company of the Japanese Takada Industry Inc. We entered the Czech market in 2002 with the goal to satisfy the growing demand of Japanese sub suppliers to the automotive industry, and build up strategic partnerships that we can utilize on the Japanese market as well as on the newly created markets throught the world.

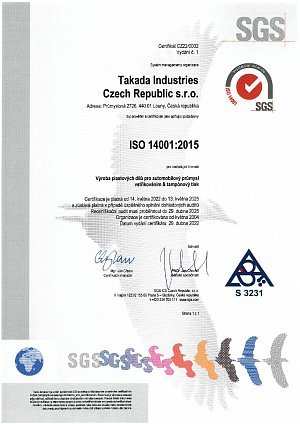

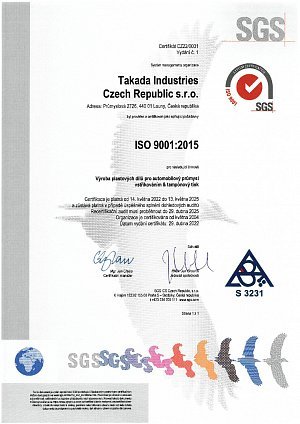

Like the mother company we are involved in the production of injection molded plastic parts mainly for the automotive industry. Requirements for quality and inspection of products are very high in this branch, and experience of the Japanese “mother”, TQM and 5S attitude provide us with a competitive advantage on the Czech market. We have a modern plant in Louny where we use the latest technologies.

Company culture is characterized with a friendly, open and pragmatic attitude of the young team and ability to act quickly given by controlling powers of the only owner, who also holds the post of President of the company. This distinguishes TiCz substantially from other foreign investors in the CR who have more complicated controlling mechanism interlinked with their foreign “mothers”.